How Do Spring Lock Washers Ensure Reliable Connections in Critical Infrastructure Like Bridges?

2025.01.20

2025.01.20

Industry news

Industry news

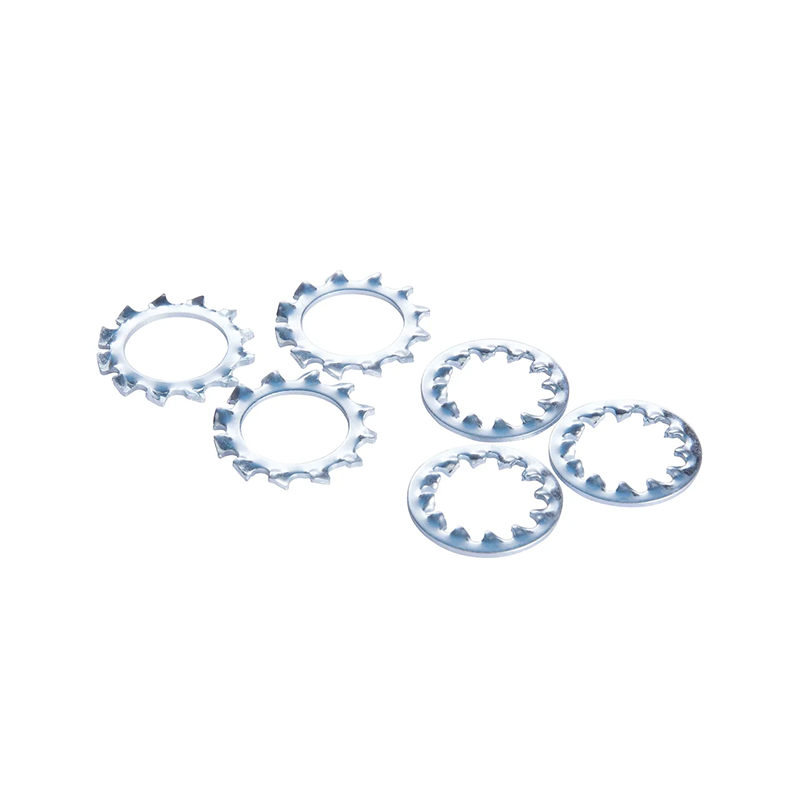

Spring lock washers are a vital component in ensuring reliable connections in critical infrastructure such as bridges, where the integrity of fastener connections is essential to maintaining safety and stability. Bridges are exposed to constant external forces, including vibrations from heavy traffic, impacts from weather conditions, and the natural movement of the structure due to temperature fluctuations or wind. Over time, these dynamic forces can cause bolts, screws, and other fasteners to gradually loosen, which can lead to dangerous situations if not properly addressed. Spring lock washers effectively prevent this loosening, providing a secure and stable connection between the various components of the bridge.

The primary function of a spring lock washer is to maintain consistent tension on a fastener. When a spring lock washer is installed, its unique spring-like design applies pressure against the fastener, such as a bolt or screw, creating a locking effect. This tension ensures that the fastener stays firmly in place, even when exposed to continuous vibration or shock. This self-adjusting mechanism of the washer allows it to adapt to the movement and forces that are common in environments like bridges, which are constantly subjected to dynamic stresses. This continuous pressure helps prevent the fastener from loosening, ensuring that the connection remains secure over time.

The importance of spring lock washers in critical infrastructure like bridges is further enhanced by the materials from which they are made. High-quality stainless steel is commonly used in the manufacture of spring lock washers due to its exceptional corrosion resistance and strength. Bridges are often exposed to harsh environmental conditions, such as moisture, humidity, and extreme weather. In such environments, the durability and long-term performance of any structural component are crucial. Stainless steel's resistance to corrosion ensures that spring lock washers retain their functionality for many years, without degrading or weakening due to environmental exposure. This makes them an ideal choice for use in infrastructure that must withstand the test of time and the elements.

In addition to their corrosion resistance, spring lock washers also offer the benefit of enhanced load-bearing capacity. Bridges endure heavy loads, particularly from vehicles and machinery, and the fastener connections must be able to handle these forces without compromising their stability. Spring lock washers are designed to maintain their locking force under high-intensity conditions, which ensures that the fasteners remain securely in place even when subjected to heavy loads. This ability to maintain a tight connection under stress is vital in preventing any potential failure or structural damage in critical infrastructure.

The reliability and performance of spring lock washers also play a significant role in ensuring the overall safety of the bridge. As a bridge is subject to continuous usage, with traffic and varying environmental conditions constantly at play, the structural integrity of the fasteners becomes a critical safety concern. A loose bolt or screw can lead to shifts in alignment, instability, or even catastrophic failure in some cases. By preventing loosening and ensuring a firm, stable connection, spring lock washers reduce the risk of such occurrences, contributing to the long-term safety and reliability of the bridge.

English

English русский

русский

Products

Products Tel: 86-574-62101087

Tel: 86-574-62101087 E-mail:

E-mail:  Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China

Add: Xiaocao 'e Binhai Industrial Park, Yuyao, Zhejiang, China